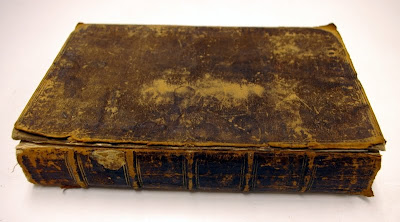

This particular book was leather bound and missing its back board.

Normally, my first response would be to rebind the book. If the book had any important book plates, I would soak that board in a warm water bath, until the book plates floated off. Then I would reattach them to the new board when dry. However, this book had a nice book plate that was painted with fugitive inks. A water bath would have destroyed it. I had to find another way to replace the board.

Since the front board was not attached, I used it as a guide to cut a new piece of board (make sure to account for the added thickness of materials at the squares). I sanded and back cornered the new board so it would tight against the shoulder. Then I cut new endpapers for the back cover, and attached them to the text block with paste.

I toned a piece of PC4 paper using and acrylics/methyl cellulose mix, to match the original leather. While that dried, I built up the corners on the remaining board.

I took the new board and covered it with the PC4 paper and put it in the press, between blotters, to dry flat. Since this paper is relatively thick, I also infilled the board with a 10 pt card (after pressing).

Because the original spine was a tight back and was still intact, I couldn't bring the new material around the spine. Therefore, I attached the new board as I would the originals, with Japanese tissue at the hinge and joint.

I attached the boards at the inner hinge first, using a strip of Japanese tissue and wheat starch paste. (This has to be done one at a time. Make sure the paste has ample time to dry). I reinforced this by adding additional tissue to the joint with PVA. I also reconstructed the head caps. I glued out a piece of tissue, overlapping on to both boards, and wrapped it around a piece of cord, the width of the spine and the height of the squares.

Finally, I toned all the tissue to match. This is the end result. (Middle: original leather board, Bottom: new PC4 board).

A blog about bookbinding, book conservation, artist's books, printmaking and interning.

Showing posts with label head cap. Show all posts

Showing posts with label head cap. Show all posts

Friday, July 23, 2010

Sunday, June 6, 2010

The Thread That Binds - Design Binding

For The Bone Folder's 2010 Bind-o-rama, the text block chosen was The Thread That Binds. I worked on this design in my book binding class. I decided to sew the text block on raised cords. The signatures were very thick, so I decorated the edge with speckled blue acrylic. The leather I had to work with was a thick, gray, morocco grain. For a color scheme, I decided to go with gray and blue. I sewed the text block with blue thread (so it would show on the exposed cords), and sewed blue and gray end bands. For the boards, I glued pieces of mat board together. This provided me with the thickness I needed to match the leather, and was easily shaped by sanding. (I had to angle the boards to be thinner at the spine, so that book could open easily). I attached these boards to the text block by fraying and pasting out the cord on them.

I pared the leather and cut away the middle with a circle cutter. I also attached this with paste, leaving extra material out at the turn in to construct the head/tail cap. Then I infilled the covers, glued down the paste papers and trimmed the turn ins. For the joint, I pared two strips of the same leather thin and pasted them down, overlapping slighting on the text block and on to the board. When those dried, I rubbed them down flush with a bone folder at the spine, then infilled the boards and cut sheets of gray Roma for the end papers. The board sheet was glued down directly on the covers. The fly sheet however, was glued onto the text block using just a thin bead of PVA along the spine and fore-edge. Finally, I painted the exposed area of the spine to match the paste paper.

I pared the leather and cut away the middle with a circle cutter. I also attached this with paste, leaving extra material out at the turn in to construct the head/tail cap. Then I infilled the covers, glued down the paste papers and trimmed the turn ins. For the joint, I pared two strips of the same leather thin and pasted them down, overlapping slighting on the text block and on to the board. When those dried, I rubbed them down flush with a bone folder at the spine, then infilled the boards and cut sheets of gray Roma for the end papers. The board sheet was glued down directly on the covers. The fly sheet however, was glued onto the text block using just a thin bead of PVA along the spine and fore-edge. Finally, I painted the exposed area of the spine to match the paste paper.

Thursday, June 3, 2010

Leather Reback - Quarter Bound

This is another book from the Syracuse University Ranke Collection that was a good candidate for rebacking. The sewing was completely intact (on raised cords), but the leather at the spine and joint was delaminated.

I was able to remove most the leather from the spine dry, and applied a thin layer of methyl cellulose to remove the rest. Then, I pasted out the spine, and lined it with Japanese tissue. While that dried, I cut strips of linen to be glued down between the cords. Then, I resewed the end bands.

Using a scalpel, I cut along where the leather meets the paper on the boards. I removed the old leather, and lifted the paper slightly. I also lifted the endpapers at the corners and at the spine, for the turn ins. (I also put some brown Morike underneath the lifted paper for support. The paper was brittle and kept breaking. Adding the Morike enabled me to handle it without causing more damage). I measured and cut the new leather and prepared it by paring, dampening with a sponge, pasting it out, and allowing it to sit for the paste to soak in. Then I reattached the boards by gluing out the linen strips and bringing them on to the board. I trimmed the linen so it only overlapped by about half an inch. Then I cut two strips of 10 point board, the exact distance from the spine edge of the board to about 1mm before the paper. This makes the transition between the new and old materials smoother. After gluing down the 10 point strips, I attached the new leather to the corners, and put some silicon release paper between the board and text block. Then I attached the new spine leather, running a bone folder along the cords to accentuate them, and leaving enough material at the turn in to construct the head/tail caps. I wrapped a piece of cord around the joint, and put the book in a press to dry.

I was able to remove most the leather from the spine dry, and applied a thin layer of methyl cellulose to remove the rest. Then, I pasted out the spine, and lined it with Japanese tissue. While that dried, I cut strips of linen to be glued down between the cords. Then, I resewed the end bands.

Using a scalpel, I cut along where the leather meets the paper on the boards. I removed the old leather, and lifted the paper slightly. I also lifted the endpapers at the corners and at the spine, for the turn ins. (I also put some brown Morike underneath the lifted paper for support. The paper was brittle and kept breaking. Adding the Morike enabled me to handle it without causing more damage). I measured and cut the new leather and prepared it by paring, dampening with a sponge, pasting it out, and allowing it to sit for the paste to soak in. Then I reattached the boards by gluing out the linen strips and bringing them on to the board. I trimmed the linen so it only overlapped by about half an inch. Then I cut two strips of 10 point board, the exact distance from the spine edge of the board to about 1mm before the paper. This makes the transition between the new and old materials smoother. After gluing down the 10 point strips, I attached the new leather to the corners, and put some silicon release paper between the board and text block. Then I attached the new spine leather, running a bone folder along the cords to accentuate them, and leaving enough material at the turn in to construct the head/tail caps. I wrapped a piece of cord around the joint, and put the book in a press to dry.

Tuesday, May 25, 2010

Leather Reback

On a recent field trip to the book conservation lab at Cornell University, I saw a few leather bound books that were rebacked with new leather (calf). This was interesting for me because most of the leather rebacks were do at Syracuse are repaired with PC4 paper. I decided to go through the stacks and find a good candidate for this treatment. This was the book I found.

My first step was to dye some of the calf leather we had to match. I used J.Hewitt aniline dyes, which start as a powder. You mix the powder with wheat starch paste (powder) and a little water to make a paste, then dilute as needed with boiling water. Dampen the leather with a sponge, then apply the dye. This picture shows the leather before (left) and after (right) dying.

My first step was to dye some of the calf leather we had to match. I used J.Hewitt aniline dyes, which start as a powder. You mix the powder with wheat starch paste (powder) and a little water to make a paste, then dilute as needed with boiling water. Dampen the leather with a sponge, then apply the dye. This picture shows the leather before (left) and after (right) dying.

While the leather was drying, I removed the old spine piece (saving the label), and cleaned the spine with methyl cellulose. I had to watch it carefully to the original end bands did not come off with the gunk. I pasted out the spine and lined it with Japanese tissue, which came up on to the end bands for additional support. Then I cut strips of linen, to fit between the cords, and glued them down with PVA. While the spine dried, I lifted the leather and end papers at the spine and corners of the boards. I reattached the boards by gluing the linen spine lining down under the lifted leather.

I pared and pasted out the new leather (one thick coat, let sit for 10 min folded over itself, add another coat) and molded it over the corners and spine. I also made sure to leave enough leather at the head and tail (after turn ins) to construct head and tail caps. I left this to dry over night.

The next day, I glued down the lifted materials with PVA. I glued out a strip of Mylar, and slid it under the lifted leather, tapped down on it gently, and slid the strip out. This ensures just enough glue gets underneath, and has less risk of the leather darkening. I also pasted out strips of Japanese tissue for the inner hinge.

While this dried, I worked on the spine label. I found a Morike similar in color to the label, and glued two pieces together. Then I glued the original label to the Morike and toned it to a better match with acrylics. I measured the spine width, and the height between cords, and cut the Morike to size. Then glued it in place with PVA. These are pictures of the end result.

I am going to try the technique on other books in the lab. The biggest problem I faced was building up my corners, which is something I need to work on. Other than that, my color is a little light, so the next time I will add a few additional coats of dye and dab them on with a sponge, to give the leather an aged look. Aside form dying the leather, this process didn't take much longer than a PC4 reback, and I like the end result better. Obviously the materials for this type of repair are more expensive, but I think it is worth it for the right books.

Subscribe to:

Posts (Atom)